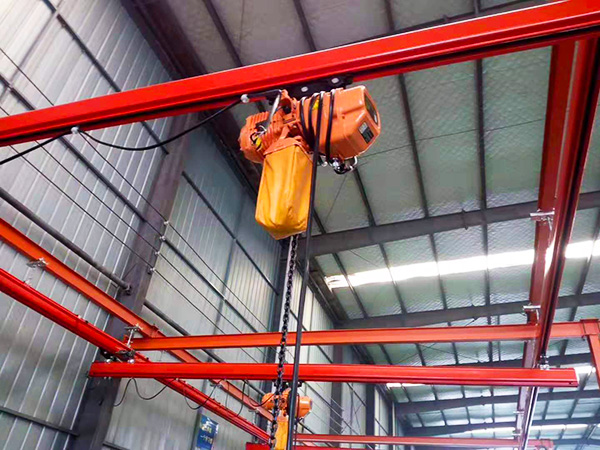

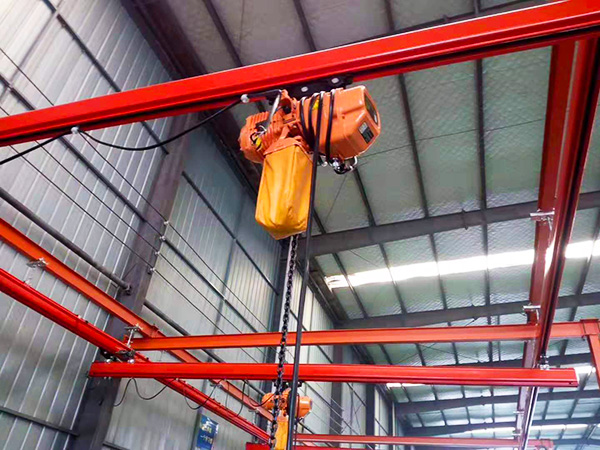

KBK rigid (flexible) crane

Scope of application

KBK crane is designed for lighter loads (not exceeding 2000kg). Parts assembly, manufacturing and processing industry, pallet shipping, injection molding, warehousing, loading and unloading, equipment repair and maintenance:

In order not to affect the operation, when a working area is not allowed to have any support structure, the flexible light composite beam suspension crane is a perfect choice. This crane system needs one that can withstand sufficient strength

Roof structure that safely supports the crane load. Customers can install multiple main beams on a set of fixed rails, which greatly improves the production efficiency. Such products are of steel structure, with a lifting capacity of 75-2000kg, and the total length of the main beam can reach 10m. Compared with the traditional beam crane, the force used in the design and handling of the closed rail is only one third of it. The design of truss rail makes the span larger and the installation layout more flexible. The equipment is composed of suspension device, track, turnout, traveling trolley, electric hoist, mobile power supply device (sliding line), control device and other components. This product is widely used in material conveying links or systems in all walks of life because it can be directly transported in the air by simply hanging on the roof or beam frame of the plant.

Product model

KBK single beam suspension crane can be simply suspended on the roof or superstructure of the building, and the crane track does not need additional auxiliary support. Whether it serves part or all of the workshop, it can be installed simply and reliably with low cost. The single beam suspension crane is composed of KBK standard components, which enables you to quickly and reliably realize the material transportation in a specific area and the positioning of various components. Large lifting capacity: 1000kg, large span: 6m.

The lifting height of KBK flexible double beam suspension crane is higher. Because the lifting hoist is suspended on the trolley between the two KBK main beams, the double beam crane can provide higher lifting space than the single beam crane. With a larger span, KBK flexible double beam suspension crane can be suspended by multiple rails, thus realizing a large span to cover a larger storage and production area. The crane can easily move by hand. However, when the span of the crane rail is greater than 6m and the crane load is more than 500kg, the large lifting weight can reach: 2000kg; Large span: 7 meters. [1] Since all components can be combined at will, the track direction can be flexibly arranged according to the building conditions of the customer's workshop to meet the special requirements of specific products and working positions in production and processing. From simple manual control of straight track to a large number of branches, semi-automatic and fully automatic control of circular track.

Product features

1. The lifting capacity can reach 2000kg, with a variety of track models and spans

2. Prefabricated standard modular design makes it easier to expand and move

3. It can be installed on any ordinary 15 cm thick reinforced concrete ground

4. The design of closed rail can reduce contamination with dirt and dust

5. Rigid fixed rail is more conducive to load positioning

6. The high-strength steel rail formed by one-time cold rolling has light weight, high precision, smooth rolling surface, and reduces the resistance of the trolley roller

7. It is widely applicable and can be used in many material handling environments

8. Very economical for a single unit of work

9. Light installation reduces installation time and cost

10. It can increase the satisfaction of operators

11. Achieve a secure operating environment

12. Rapid return on investment can be achieved by improving production efficiency

2022-4-6 14:11:51

2022-4-6 14:11:51